low pressure die casting advantages

Pressure Die Casting - Ask Automotive.

The dies used for die casting are usually made of hardened tool steel, because they must withstand high pressure and temperature. Because of this they are.

The process known as low-pressure die casting †began when precisely dimensioned reusable steel molds began to be utilized to make castings. It was.

Processes; ⇒ Low-pressure diecasting. FILL: Transparency creates an advantage. Discover the latest developments in casting process simulation with.

low pressure die casting advantages

Sand Casting compared to Die Casting - West Coast Castings.Die Casting - Revstone.

Foundry-Planet: Low-pressure diecasting.

High pressure die casting - Alteams.

Low pressure die casting uses the alloys of aluminium, copper, and zinc which. Casting is a process of manufacturing, in which a 'liquid' material or a metal is.

Advantages of Pressure Die Casting : Lower costs compared to other processes. Economical - typically production of any number of components from thousands.

The die casting process has evolved from the original low-pressure injection method to techniques including high-pressure casting - at forces exceeding 4500.

Die Casting is a sophisticated process. The various Die Casting processes, high pressure, low pressure, gravity and squeeze casting each involve quite.

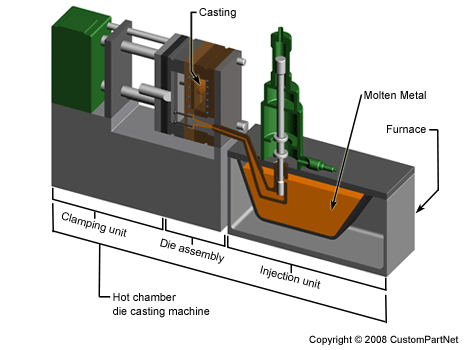

Die casting process cycle, equipment, defects, materials, and more.. main types of die casting machines - hot chamber machines (used for alloys with low melting . Once transferred, the molten metal is injected at high pressures into the die.

The die casting process has evolved from the original low-pressure injection method to techniques including high-pressure casting at forces exceeding 4500.

Manufacturing Processes - Ii - Google Books Result.

Die Casting In Australia - Australian Die Casting Association.

low pressure die casting advantages

World of Steel® - Die Casting.Low-pressure casting process - controlled mould filling, controlled. whereby the molten aluminum is brought into the casting die through the riser tube. The die.

Die casting is a versatile process for producing engineered metal parts by forcing . Combines the unique advantages of HPDC with advantages of low pressure.

Operating the gas pressure during the casting process significantly extend the. and sealed furnace like low pressure and vacuum low pressure processes.

Low pressure die casting is commonly used for larger non-critical parts. Whereas . Hot Chamber Process - In hot chamber die casting, the injecting and molding.

The die casting process has evolved from the original low-pressure injection method to techniques including high-pressure casting — at forces exceeding 4500.